quality policy

Quality Check Process

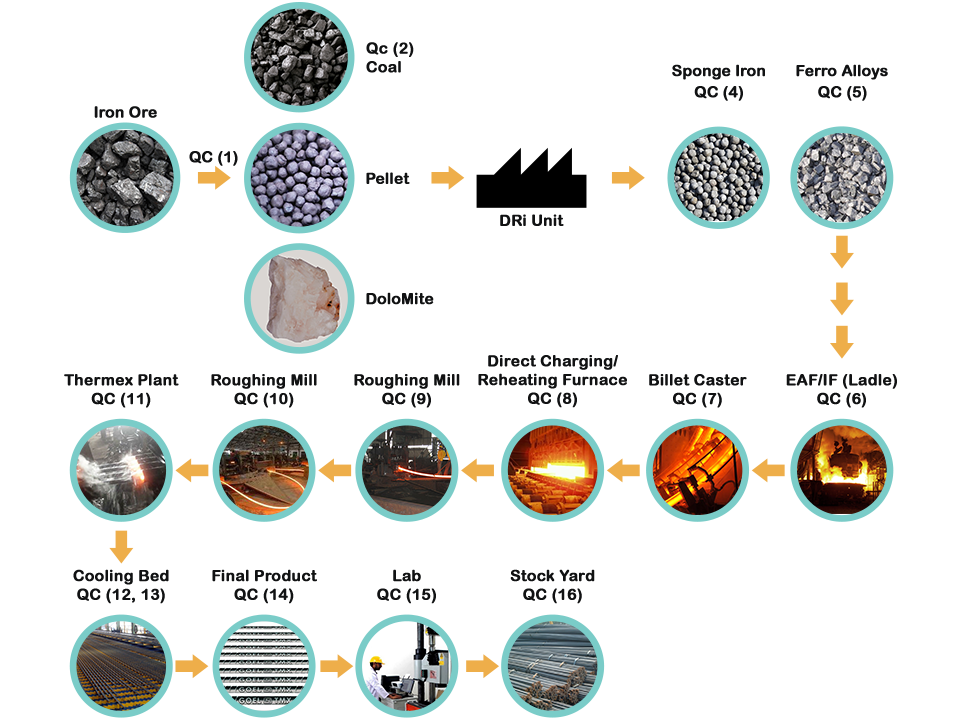

Goel TMT follows the practice of rigorous quality checks at each stage of production right from the analysis and testing of raw materials to the end-product.

Raw material quality checks - the process involves the material testing through stringent visual and chemical checks at the manufacturing stage itself. Our expert team of technicians makes sure of the process parameters such as the temperature of the bar, the diameter, etc. before packaging and dispatching the end-product. This also includes testing of physical and chemical properties of the bars at Our Testing Laboratory uses State-of-the-art testing facilities like the Spectro Metal Analyzer, which is used for chemical analysis, two fully computerized UTM-100 MT capacity machines for testing the physical properties of the bar.

| QC Check Point | Activity |

|---|---|

| 01 | Chemical Analysis of Iron Ore. |

| 02 | Chemical Analysis of Coal, Pellets & Dolomite. |

| 03 | Monitoring Process Parameters to Ensure Desired Finished Product. |

| 04 | Chemical Analysis of Sponge Iron. |

| 05 | Chemical Analysis of manganese Ore & Finished Product. |

| 06 | In Process Chemical Analysis of Liquid Metal & Refining for Desired Properties. |

| 07 | Temperature Check, Chemical Analysis & Visual Inspection of Billets. |

| 08 | Re-heating Furnace Temperature Check. |

| 09 | Checking of Stock Size. |

| 10 | Temperature Monitor at Entry in Thermax. |

| 11 | Monitoring of Thermax Pipe. |

| 12 | Temperature Monitor at Exit of Thermax. |

| 13 | Equalizing Temperature Monitor. |

| 14 | Checking of Section weight and Bar Straightness. |

| 15 | Final Physical And Chemical Analysis of Finished Product. |

| 16 | Heat Number wise Stocking at Finished Material Yard. |